Marine loading arms are an integral part of an LNG gas plant. They are the fluid transfer mechanism which transfers the LNG from the dock to the floating transport vessel.

Pressure Dynamics modified the hydraulic systems of four LNG marine loading arms to prevent all four marine loading arms from being taken out of service when only one marine loading arm required hydraulic maintenance work.

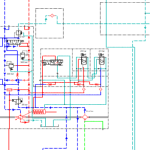

The arms are powered by a common hydraulic power unit and at each of the arms the common hydraulic line branched off to provide fluid power required for its movement. To add isolation valves, the team started with a laser scan survey of the arms to capture the precise location in 3D of each of the existing hydraulic tubes and support structures.

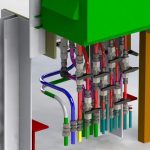

The actual modifications to the four loading arms were successfully completed on-site in 72 hours. This 3D model shows the isolation valves installed in tight spaces. The use of technology to scan and create a 3D model helped improve the quality and reduced the lead time required to complete the project.

Interested to know more about the use of 3D modelling for Oil & Gas systems? Talk to our Engineering Manager, Reza Tavakoli – FIEAust.