Fixed plant inspection and maintenance of hydraulic systems in the mining industry are critical for machine reliability and safety. In particular, balance machines have a stored energy in the form of counterweights. This counterweight is used to balance the weight of the boom and the product it is conveying. The boom moves vertically and horizontally using a hydraulic system.

Pressure Dynamics SME’s add value by reducing unplanned downtime due to hydraulic system and component failures.

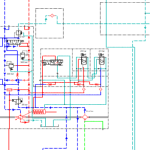

We completed a planned maintenance inspection of a reclaimer hydraulic system and identified corrosion issue on critical pipework whose failure could cause uncontrolled movement of the boom.

Once identified and reported, we manufactured, tested and replaced the corroded pipework in the next planned shutdown.

Pressure Dynamics was able to identify a potential failure not currently captured on the maintenance inspection paperwork, manufacture the parts required, generated a safe work procedure then implemented the scope of work and adjusted maintenance inspections to include inspection of critical pipework in the future.