Pressure Dynamics was engaged by a client to review the design of a pneumatic control system used to operate the safety doors on an offshore semi-submersible production unit.

Due to various design issues, the pneumatic control system including the cylinder failed and the doors were frequently out of service.

Upon conducting a site survey and review of the control system design by the engineering team, it was found that the cylinder is not robust enough to carry the applied load during the operation and the pneumatic control system is not designed to control the speed of the door specially at the end of the stroke to reduce the shock load applied the door and its mechanism.

Pressure Dynamics designed and built a new pneumatic cylinder which was tested in the workshop for 60,000 cycles using a test set-up which replicated the actual condition of doors operation.

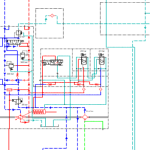

We also proposed some modifications to the pneumatic control system to better control the speed at the end of the stroke. The pneumatic control system was modeled and simulated with the proposed solution using Automation Studio software to demonstrate the practicality of modifications.