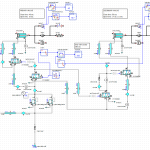

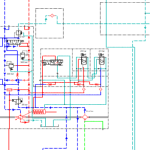

Pressure Dynamics recently assisted one of our clients to identify the root cause of fluctuation on time delay between operation of primary and secondary pneumatic driven Blow Down Valves (BDVs) by modelling and simulation of the pneumatic control system used to drive the valves.

The simulation results showed that CV (Flow Coefficient) of the flow control valve used to control the time delay between BDVs is not suitable for the application.

Modelling and Simulation software – integrating our subject matter expertise, industry experience, and know-how – are applied by Pressure Dynamics’ Hydraulics and Lifting Engineers for system design and modification verification, troubleshooting, and optimization.

Depending on the application, Pressure Dynamics use different software for modelling and simulation of hydraulic and pneumatic systems. Such software include, but are not limited to, SimulationX (ESI Group), Automation Studio (Famic Technologies Inc.), Matlab (MathWorks).